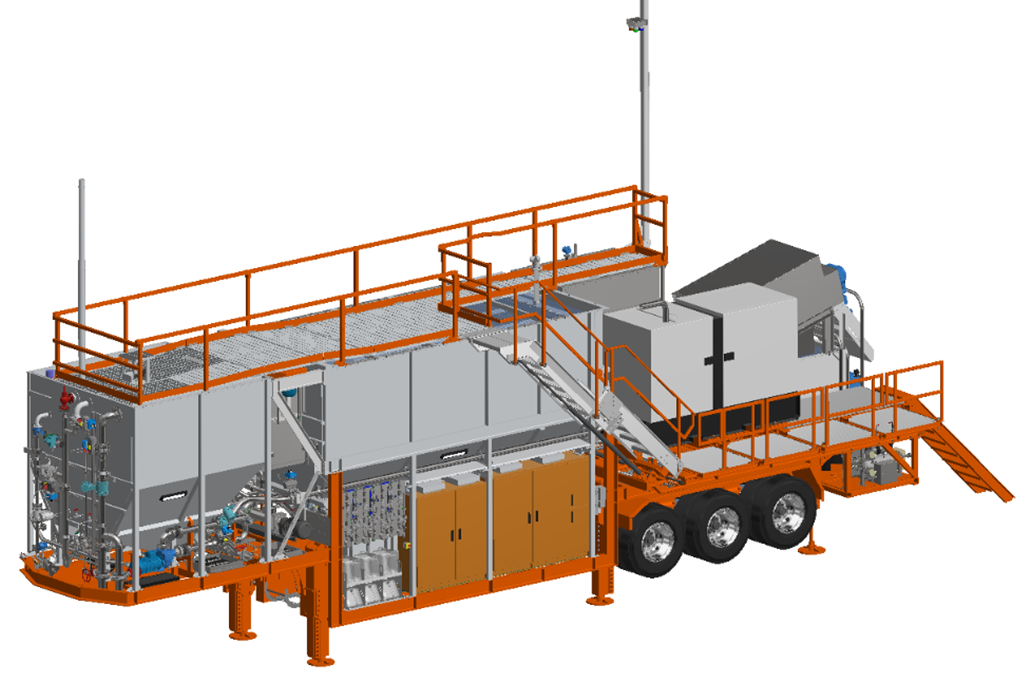

WORKOVER SOLIDS TREATMENT TRAILER

A major player in the coal seam gas field engaged CS GAS to design and manufacture a solution for workover waste fluid treatment services.

The Client’s objective for the project was to remove the requirement for daily water tanker movements, vacuum trucks, and to remove the flow of solids through gathering networks into holding ponds.

Location: Surat Basin, QLD

Industry: Coal Seam Gas Industry

Services: Engineering, Fabrication

Equipment: Waste fluid treatment services

The challenge

The coal seam gas workover market in Queensland exceeds 1,000 workovers annually in the Surat Basin alone. While rig packages have been customised for high performance with turn-around times well-to-well, typically in 2-3 days, management of water and waste solids remains a logistical effort.

This volume of waste fluid treatment generates ongoing costs. Either upfront costs, at suitable facilities or land sprayed, or long term costs within the current CSG pond infrastructure (where permissible).

These conventional methods of waste fluid treatment services result in the following:

-

- Non-productive time whilst waiting on fluids for workover sites, especially those a larger distance from clean water supply locations.

- Consumes rig time in the removal of waste fluids at the end of each workover program.

- Creates considerable heavy vehicle movements on field sites and local road infrastructure with associated issues.

The solution

The Workover Solids Treatment Trailer (“WSTT”) is a single trailer designed to directly connect to the gathering networks and initial upload tanks during rig workover operations. It processes the water / solids streams at the maximum rates that a typical CSG workover unit can achieve.

The WSTT processes the incoming ‘dirty’ water and outputs it into two streams, clean water and spadable solids. The clean water is either injected into the gathering network or back to the workover.

The system is a single trailer “roll in, roll out” set up with all systems such as power generation contained in one mobile package. As an all-in-one unit, there are no impacts to a typical workover rig up / rig down cycle. The WSTT removes a significant volume of vehicular transport, whilst offering improved safety, sustainability, and commercial benefits for clients. The WSTT is remotely operated and monitored, so there’s not a significant increase in crew numbers onsite to support its operation

The outcome

This solution was designed in house by the CS GAS Engineering Team, manufactured onsite at Acacia Ridge, with all fabrication, E&I and remote operation supplied by CS GAS as a turnkey solution.

The WSTT provides for a tremendous reduction in the extent of trucking operations (Estimated at 250,000km’s pa for this client) required for typical CSG workovers with a cost, safety, and environmental improvement.

The Solids produced by the process can be re-used or disposed of safely and effectively.

+61 7 3273 4222

14A/243 Bradman St,

Acacia Ridge Qld 4110

sales@csgas.com.au

Follow us

Qld Electrical Contractor Licence Number 71421 | NSW Electrical Contractor Licence no. 386286C | QLD Labour Hire Licence: LHL-04228-JRR8S